Material That Withstands time,

Design Inspired by Subtlety and Precision

STAINLESS BEYOND TIME

Adding Sensibility to a Rust-Free Essence.

TITAMAX is a premium building material brand that applies a refined design language to stainless steel, a material known for withstanding the passage of time. Durability, precision, and aesthetics. We bring these three values together in a single material.

“Function is the foundation, sensibility is the essence.”

This is how TITAMAX defines stainless steel.

THE BEAUTY OF

RESILIENCE

The meeting point of permanence and beauty.

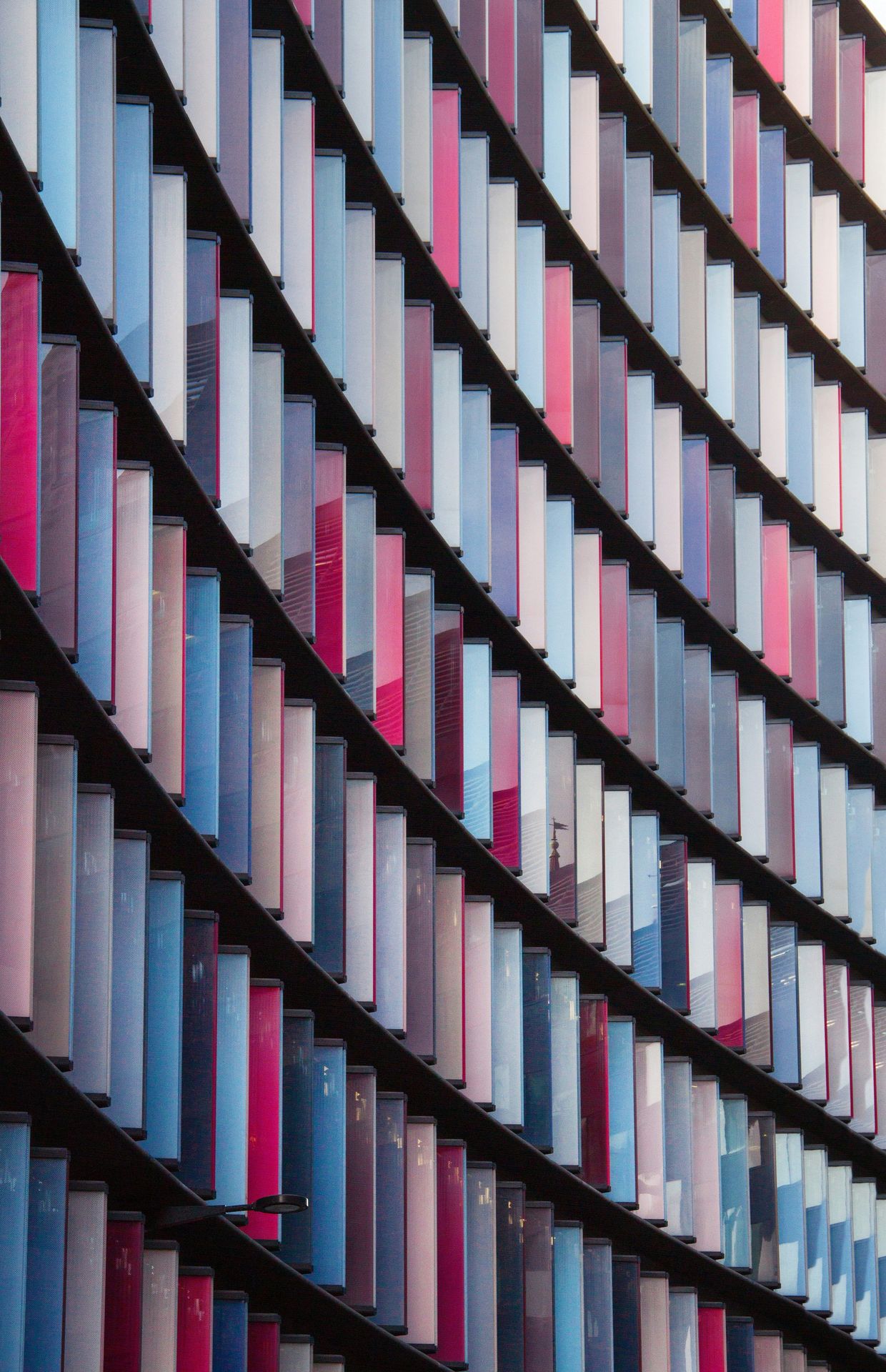

Stainless steel does not change. It resists moisture, air, heat, and light with strength. What we add is the depth of mirror finishes, the flow of hairline textures, the rhythm of embossing, and the subtlety of color. We call it a material that is alive forever. It is not simply a building material that reflects light, but a design that interprets space.

That is the surface of TITAMAX.

CRAFTED BY HWANGKUM ST

Design built upon technology.

TITAMAX is created through the technology of Hwangkum ST, Korea’s largest stainless steel service center. Precision cutting, brushing, embossing, and color plating. Through a process where machines and craftsmanship come together, the ideas of designers become reality. When technology is strong, design becomes free. We make that freedom possible.

OUR ORIGIN, OUR MOTIVE

Why TITAMAX?

We wanted to redefine stainless steel, once seen only as an industrial material, as a language for architecture and design. Not as a colorless metal, but as a medium that conveys light, warmth, and atmosphere. TITAMAX began with a question about the potential of materials. Now, that question has become a new answer, expressed through the hands of architects and designers.

DESIGN MEETS PERFORMANCE

The perfect balance of function and emotion.

TITAMAX is strong. But more importantly, it is beautiful. Exceptional resistance to weather and scratches, lasting color, precise sizing, and flexible customization. On top of all these features, your design comes to life. TITAMAX is not just a material. It is a partner in creating spatial experiences.

What is TITAMAX?

TITAMAX is a premium stainless steel building materials brand presented by Hwangkum ST. It combines the inherent durability of rust free stainless steel with refined surface finishes such as mirror polish, hairline, and embossing. These are further elevated by sophisticated form design and expressive color plating. A material that retains its brilliance over time, stainless steel that inspires architecture. TITAMAX is more than just a material, it is a design language that shapes space.

From precision to perception, a timeline shaped by both

2025

Inco Color Line Unit 3 Installation

2021

Embossing-D Line Installation

Inco Color Line Unit 2 Installation

Nano Coating Line Installation

Titanium Coating Line Unit 5 Installation

Titanium Coating Line Unit 6 Installation

HL Coil to Coil Line Installation

Physical Vapor Deposition (PVD)

PVD is a surface coating technology that vaporizes metal in a vacuum and deposits a thin film onto the surface of a material.

Commonly used metals include titanium and chromium, which create durable surfaces with rich colors.

Inco Coloring Process

The Inco process is an electrolytic coloring technique that forms an oxide layer on the surface of stainless steel to produce inorganic colors. Instead of using paints or pigments, it creates color through light interference on the metal’s surface itself. This method produces a uniform and premium finish, with deep, varying hues depending on the viewing angle and lighting.

Surface Finishing Process

The surface of stainless steel creates unique textures and moods depending on the finishing method. Hairline (H/L) features subtle, straight lines that evoke a calm and sophisticated feel, while Mirror (MR) offers a reflective, mirror-like finish that makes spaces appear more open and luxurious. Bead Blast provides a matte, clean texture through fine particle blasting, and Vibration (VIB) creates a dynamic and three-dimensional look with intersecting patterns. Each surface finish goes beyond mere appearance, serving as a key element in enhancing the character and elegance of a space.

Embossing Process

The embossing process creates three-dimensional patterns on metal surfaces, adding a distinctive texture and visual depth. It enhances slip resistance and wear resistance while highlighting design elements, achieving both functionality and aesthetics.

Nano Ceramic Coating Process

The NC (Nano Ceramic) coating enhances both durability and cleanliness by combining ceramic and fluorine technologies. The ceramic layer ensures strong resistance to wear and heat, while the fluorine layer provides water-repellent and stain-resistant effects. This synergy protects the surface from scratches, discoloration, and contamination, making it well-suited for high-end architectural and interior finishes.